Esther Trilsch

esttri

About Me

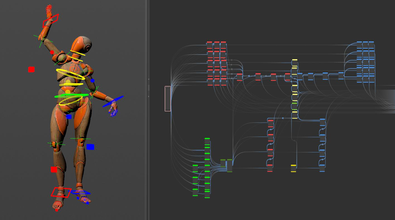

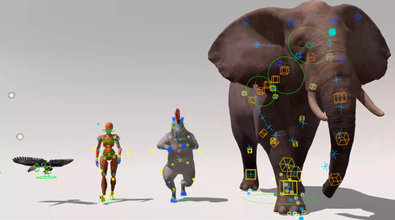

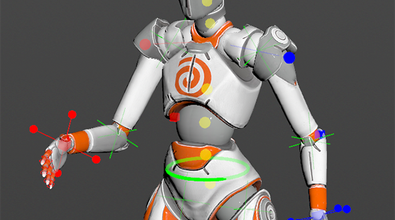

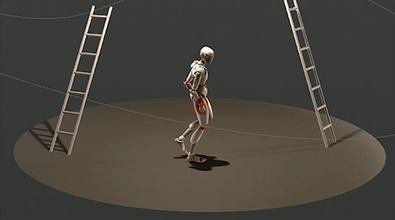

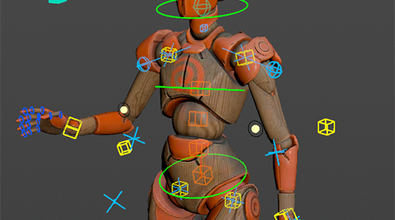

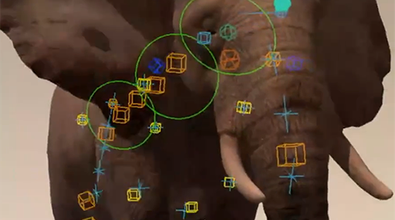

Esther Trilsch is a Senior Character TD at SideFX. She started her career as a character TD apprentice at Walt Disney Animation Studios working on Zootopia, and worked at RiseFX as a Character Supervisor and Pipeline TD. Combining her focus for both the creative side of anatomy and deformation, as w... more

Esther Trilsch is a Senior Character TD at SideFX. She started her career as a character TD apprentice at Walt Disney Animation Studios working on Zootopia, and worked at RiseFX as a Character Supervisor and Pipeline TD. Combining her focus for both the creative side of anatomy and deformation, as well as the technical side of RnD, she found her sweet spot in the building of innovative structures and tools for character workflows. less

専門知識

Developer

Connect

LOCATION

Berlin,

Germany

ウェブサイト

Houdini Engine

ADVANCED

キャラクタ & アニメーション | Animation

Availability

Not Specified

My Talks

My Houdini Content

Recent Forum Posts

How to see properties in APEX network view? 2024年7月14日7:46

They are available via the right click menu. You will get a small dialogue to get and set them there.

Rigscript Component vs Autorig Component? 2024年7月13日18:40

The underscores are related to templates nodes in APEX aka all the nodes that look like nodename<Float> for example. Apex always wants to know on what kind of data you operate on because its a fixed type system. In apex script we can usually figure out that type based on what you are doing. If the type can not be figured out you need to give it a hint.

sois then the same as When you look at a graph with NODES. So the underscore is the absolute bare bone fallback option, when we really have nothing to work with to figure out what the type should be. Ideally you need to use it almost never. Another and much more pythonic way of giving a type hint is

The daily build that is about to come out will handle a lot more of those cases automatically for you btw.

Soshould do the trick then. Yay.

The convert case is one of the few functions that actually does not just need one but 2 types. Which makes it much trickier to automatically fetch. We can look into a more specialized handing for that one. the trailing underscore is also an inconsistency that we can look into.

so

nodename_Float()

nodename<Float>

nodename(valuetype=Float)

The daily build that is about to come out will handle a lot more of those cases automatically for you btw.

So

geo.setPrimAttribValue(prim, 'name', 'test')

The convert case is one of the few functions that actually does not just need one but 2 types. Which makes it much trickier to automatically fetch. We can look into a more specialized handing for that one. the trailing underscore is also an inconsistency that we can look into.

Rigscript Component vs Autorig Component? 2024年7月11日16:06

The spider example in the content library uses the rigscript components and you can see it a bit more in action and there should be a few notes in there about what exactly it does and why we use it. I hope that helps